GWD – DIGESTER

- Revolutionary technology in organic waste management Continuous Process and feeding

- Reduce Waste 95-98% and convert food waste into grey water

- Customized Enzymes to achieve stable and consistent output

- On-site Solution

DIGESTER PROCESS FLOW:

-

Food Waste

Food waste generated from production.

-

Waste Inputs

Food waste is put into the Digestor.

-

Micro-organisms

Proprietary Biomedia & microbial mixtures are added.

-

Discharge

Effluent is filtered safely through a screen into existing sewage infra-structure.

-

Breakdown Process

The food waste is digested into smaller pieces eventually trans-forming into liquid effluent.

-

Oxygen

Aerobic digestion begins once oxygen is added to the mixture through churning.

Before

After

GWD – COMPOSTERS

- Revolutionary technology in organic waste management

- Process organic waste to fertilizer within 12 hours

- Reduce Waste by 80-90% with output as fertilizer

- Customized Enzymes to achieve stable and consistent output

- On-site solution

COMPOSTER PROCESS FLOW:

-

Food Waste

Food waste generated from production.

-

Waste Inputs

Food waste is put into the Composter.

-

Enzymes

Enzymes mixtures are added.

-

Discharge

Fertilizer is being discharged from the machine.

-

Breakdown Process

The food waste is composed into smaller pieces eventually trans-forming into fertilizers.

Before

After 2 Hours

After 10 Hours

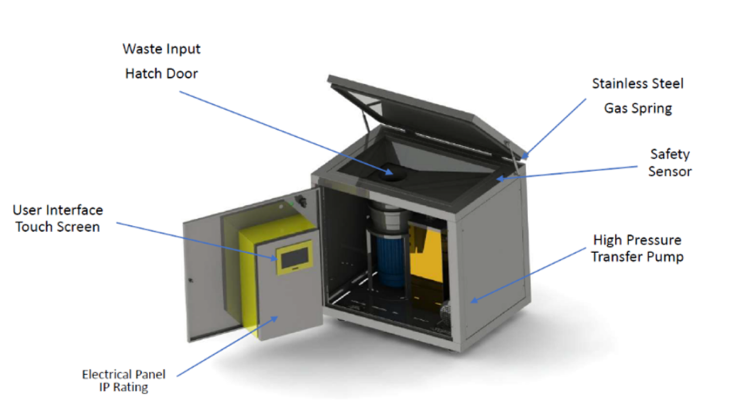

INFEED WASTE STATION

- Super grinder to breakdown food waste

- Equipped with pump or dewatering system

- Reduce Waste Volume 90% and convert food waste into slurry form

- Able to process at High Capacity (100kg/hour)

- On-site compact Solution

INFEED STATION:

PRODUCT SCHEMATICS

Small footprint and high efficiency can place next to source of waste in the kitchen or working table underneath.

Grind small bonds, lobster shell and other food wastes. Build in pump and sensors fully automatic transfer up to hundred of meters.

2 mode operation, auto stop or continuous non stop for high volume of waste input.

Reduce waste volumetric up to 90% and achieve productivity up through zero transfer by man on food waste. Capacity approx. 5Kg per 2 min.

COMPARISON OF WET & DRY SYSTEMS

A breakdown of the Pros and Cons of both wet and dry system

COMPOSTER

DIGESTOR

Compost Output

Grey Water Output

Wider range for input allowable and machine tolerance level is higher

Input range is lesser than composter and lower tolerance level.

More expensive

Cheaper cost

Higher Opex cost

Lower Opex cost

Higer energy consumption

Lower energy consumption

No water usage

Require water supply

No discharge

Discharge (compliance to PUB Trade Effluent.)

BIO – HYBRID SYSTEM

- No trade affluent issue using our proprietary closed loop system

- Low energy consumption thus achieving low Opex

- Waste can be continuously fed into the system unlike batch composters

- Organic compost output of 15-20%

- Compact machine footprint. We do not require massive space to install machine

- Proprietary shredder to enable any type of food waste to be disposed into system

HYBRID SYSTEM PROCESS FLOW:

-

Food Waste

Food waste generated from production.

-

Waste Inputs

Food waste is put into the Digestor.

-

Phase 01– Digestion

Proprietary biomedia and microbial mixtures to act-ivate phase 1 digestion.

-

Discharge

Compost is being discharged from the hybrid system.

-

Phase 02– Composting

The sludge is then composted, dried, and reduced in volume at this stage eventually turning into compost.

-

Conveyed

The digested sludge is then conveyed to the second chamber to composting.

PLASMA ASSIST MACHINE

Green Waste Technology’s innovative PAE system – an on-site mobile marvel. It deftly transforms a spectrum of waste, spanning munipal, organic, agricultural, food, and animal residues, into highly concentrated, recyclable ash, reducing volume by an impressive 95%.

This ash finds second life in road and building construction, as organic compost for landscaping, or as a safe haven for hazardous biomedical waste. Moreover, precious metals can be harvested from valuable E-waste using this versatile system.

TRADITIONAL METHOD:

THE OLD SCHOOL WAY:

Waste Bin &

Sorting Cost

Storage/

Processing Cost

Logistics &

Segregation Cost

Energy Cost/

Pollution Cost

NEW METHOD:

PAE ON-SITE SYSTEM:

95% Volume Reduction Odorless & No Toxics Emission

Ash

Low Cost PAE

System

All Kinds of

Organic Waste

THE CORE FEATURES OF OUR PAE SYSTEM

Versatile Waste Conversion

Our on-site mobile green system efficiently transforms various waste types into a concentrated, 5% recyclable ash.

Resourceful Ash Applications

The recyclable ash finds multiple uses, serving as a valuable resources for road and building construction, as well as organic compost for landscaping.

Hazardous Waste Solutions

The PAE system extends its capabilities to handle hazardous biomedical waste, ensuring safe disposal and potential recovery precious metals from E-waste.

Plasma Assisted Technology

Leveraging advanced plasma assisted technology, the system breaks down organic matter using negative ions.

Econimical & Eco- Friendly

Operating at low temperature and without fuel or gas requirement, the PAE system offers an environmentally conscious and cost- effective waste treatment process.